Smart clothing, wearables, and e-textiles. These words are buzzing around the technology industry more than ever. Smart clothing is the term used for any item of clothing that has been enhanced to essentially become an IoT (Internet of Things) integrated and enabled product. Smart clothing has been produced to do a wide range of things, from monitoring vital signs to monitoring sports performance, to simply kicking in some added extra heat to your winter jacket whilst you are exploring during the harsh winter elements. This smart clothing industry is projected to grow exponentially, as available technology progresses and can be integrated for new bespoke applications and functions. This is where printed electronics come into play.

Printed electronics is a well-established industry, Reid Print Technologies has been manufacturing Printed Electronics for over 30 years to add a little perspective here. The family of printed electronics products traditionally comprised of membrane switches, capacitive switches, decals, overlays, and HMI Panels. These traditional products are still very much in demand worldwide, however newly developed techniques for advanced manufacturing means these printed electronics can harness these processes to produce wearable flexible circuitry and sensor technology.

Flexible sensor technology, stretchable circuitry, and other printed electronics are the perfect fit for the product development of wearable smart clothing for many undeniable reasons. Flexible printed electronics are thin, flexible, lightweight, and low cost to manufacture. This technology can also be integrated into a range of different types of sensors to accommodate every possible application including:

- Temperature sensors

- Biosensors

- Heart and Respiratory Rate

- Force Sensors

Printed electronics have such a vast capability set, it’s a no-brainer and an avenue that has received an increase in interest and traction amongst the wearables industry. For more information on Smart Clothing and Printed Electronics contact sales@reidprinttechnologies.com.au or 1300 765 533

Don’t Forget to Follow Us on our socials: Facebook | Instagram | LinkedIn

A graphic overlay can transform the interface of any product, machine, or equipment. Graphic overlays are a critical component to a membrane switch, capacitive switch, or touchscreens as graphic overlays are a touchpoint between the business brand and the end user or consumer. Therefore, graphic overlays play a critical role in product branding as well as providing user-friendly functionality to a product.

Industries Served

Graphic overlays have provided these benefits to a variety of industries across a diverse range of products including:

- Automotive

- Consumer

- Defence

- Electric Vehicle

- Industrial

- Marine

- Medical

- Mining

- Safety Equipment

- Sporting

Features of Graphic Overlays by Reid Print Technologies

Graphic overlays manufactured by Reid Print Technologies also offer the following beneficial features:

- Anti-glare

- Chemical resistant

- Heat resistant

- Scratch resistant

- UV Resistant

- Water resistant

The Print Process

At Reid Print Technologies, we have an extensive range of materials on offer. By using a variety of textured materials, the finished graphic panel can vary in look and feel, enabling us to achieve unique design pieces for each customer. The overlays generally begin as a clear piece of polyester or polycarbonate material. Once a base material has been selected, we begin by screen-printing or digitally reverse printing (sub-surface) on to the material, this ensures the ink is protected from wear and scratching ensuring longevity of the overlay panel. Then selective textures are printed on the front side (top surface printing) of the material to allow for LED and LCD windows. A variety of base materials are available, we recommend using polyester for any application where the panel will be flexed. If the panel is simply for badging or identification purposes polycarbonate is suitable. Both polyester and polycarbonate offer a variety of surface finishes from matte to high gloss and even hard coated gloss.

Unlimited graphic design options are a key feature of graphic overlay panels. Embossing, raised printing, die or laser cutting and the inclusion of clear or tinted windows for LCD and LED displays are just some of the effects which Reid Print Technologies can incorporate into an overlay panel to enhance its appearance and ease of use.

How to Contact Us?

For more information on Graphic Overlays and Graphic Overlay Design contact sales@reidprinttechnologies.com.au or 1300 765 533

Don’t Forget to Follow Us on our socials: Facebook | Instagram | LinkedIn

What is a PTC Heater?

PTC Heater stands for Positive Temperature Coefficient Heater. This is the technical wording for a flexibly printed wearable heater. Reid Print Technologies have mastered this technology on a large mass manufacturing scale. This has given Reid Print Technologies the ability to assist customers from prototyping, all the way through to product commercialisation in the wearables space.

PTC Heaters are a newer technology to hit the market utilising electronic print techniques. In short, the PTC Heaters screen printed onto a flexible substrate, which in turn enhances the piece of material to essentially become a paper-thin heater. These heaters are printed through using specialised inks that are resistive, conductive and a positive temperature coefficient. Flexible Printed PTC Heaters have overtaken the need for traditional heating methods. This new avenue of technology is on offer at Reid Print Technologies.

Due to the lightweight characteristics, PTC heaters are the preferred technology amongst industry applications where space and weight are a limitation. The manufacturing of this technology is very comparable to printed circuitry. Therefore, Reid Print Technologies has the optimal production processes to manufacturing PTC heaters at a large scale. This is particularly beneficial for businesses who are ready for full commercialisation.

What are the Benefits of Flexible PTC Heating Technology?

The flexible heater market is expected to have an exponential increase in demand by 2027. This is due to the increase demand of a technology that is not restricted by weight and size. A variety of industry are undergoing massive technological advancements and are hence looking to adopt more robust technological solutions.

The added benefits of opting for flexible printed PTC heaters by Reid Print Technologies is the easy integration that our products offer for both, new and existing products. Other benefits of flexible printed PTC heaters characteristics include:

- Self-regulating

- Ultra-thin

- Durability in extreme environments

- Made to order offering full customisation on shapes, sizes, resistances, and configurations

- Battery operated so you are not restricted to a power point as the power source

What Industries can utilise this technology?

Flexible PTC heater can be used across a variety of industry, and many industries that have not yet been discovered. Some of the industries that currently use the flexible PTC heat technology include:

- Apparel: As seen in heated clothing items such as jackets, gloves, and boots. An example of this is motorcyclists using the heating technology to keep them warm when they are riding in the harshest elements.

- Defence: PTC heating has been utilised in soldier uniforms and boots to help combat harsh weather environments.

- Medical: Often used in bedding to help keep patient temperatures regulated in and out of surgery.

- Automotive and aerospace: The automotive industry has been reaping the benefits of this technology for several years. This heating technology is often incorporated in the heated seating, steering wheels, and defogging or de-icing function in mirrors and windscreens.

- Sports and recreation: PTC heating elements have also been historically used in the sporting industry for athlete muscle recovery.

- Consumer: A unique application of flexible PTC heating elements in the consumer product market is utilising the heaters as a defogging agent in camera lenses. This market demand has increased as the number of free-lance photographers has increased around the world.

The possibilities for flexible printed heaters are endless. As this technology becomes more widely known the demand for it has been forecasted to increase exponentially. For more information on Reid Print Technologies flexible PTC heating solutions contact us on 1300 765 533 or email us at sales@reidprinttechnologies.com.au.

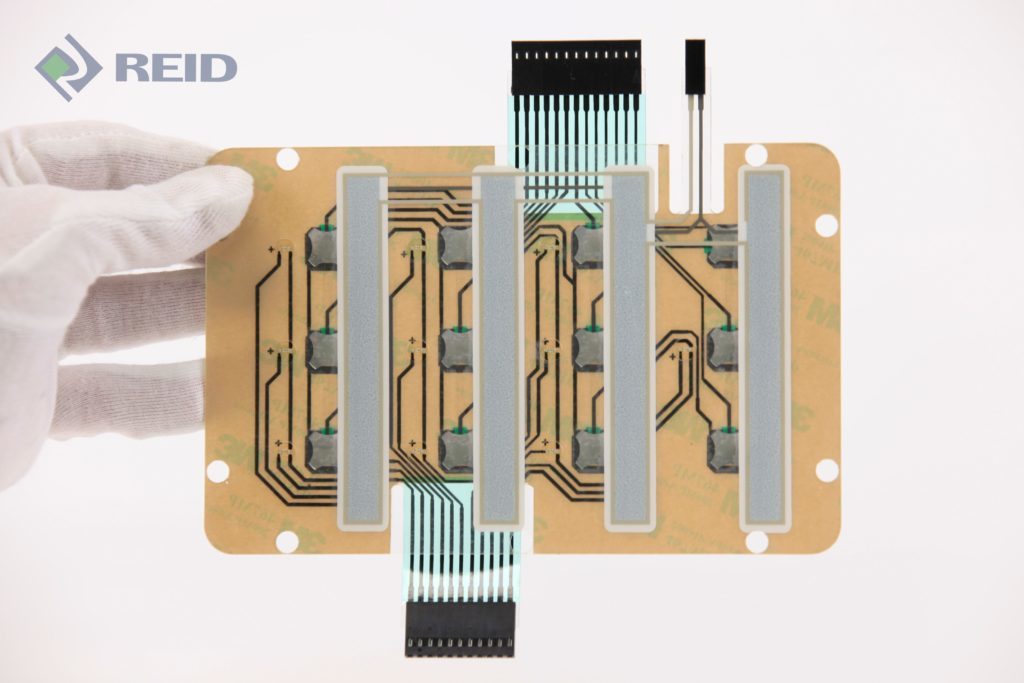

Membrane switches are the economical alternative to conventional mechanical switches. With the increased popularity of membrane switches in a wide range of industry and electronic applications, it is important to fully understand what you want your membrane switch to be able to achieve. Membrane switches can take the form of a complete graphic interface panel or the simplified flexible printed circuitry. Flexible printed circuitry is also well suited for silicone key mats, where traditional rigid PCBs are not well suited. When correctly engineered membrane switches are the hard-wearing and reliable form of switch technology.

The benefits of opting for membrane switch solutions include:

- Hard-wearing and durable in extreme environments

- Adhesive backed for easy installation

- Capability to die or laser cut to any shape

- Variety of surface finishes available

- Reliable and compact

- Ability to be die or laser cut into any shape

- Variety of surface finishes available

What is the process of manufacturing a membrane keypad?

The first step in choosing your membrane switch panel is to design the overlay that will stay unique to each order, ensuring the Human Machine Interface (HMI) aligns with the brand of the business. Graphic Overlays enable full design capabilities. These overlays generally begin as a clear piece of polyester or polycarbonate material. Once the base material has been selected, it is then screen or digitally reverse printed on to the material. This protects the ink from wear, scratching, and tear, ensuring the longevity of the overlay panel. Selective textures are printed on the front side (top-surface printing) of the material to allow for LED and LCD windows if desired.

Where can you find a membrane switch?

Membrane switches have historically been utilised in a variety of industry. Reid Print Technologies manufactures across the industries of:

- Medical

- Defence

- Aerospace

- Industrial

- Consumer

- Transport

- Electronic Vehicles

- Marine

- And many more

What are the different types of membrane switches?

Switch assemblies can be divided in to two main groups, that being tactile and non-tactile. Each of these groups are more suited to different industries and each perform a different function on the circuit board.

Tactile: Tactile switches a designed to give feedback response when the switch has been pressed by a finger in order to provide this tactile feedback, stainless steel or polyester domes are used. The number of sizes shapes and actuation forces of domes are vast. Reid Print Technologies sales engineers can assist you in choosing the dome that is suitable for your application.

Non-tactile: Non-tactile switches are more reliable and have a longer life cycle but does however require separate feedback to the operator such as a beep, light or change in visual display. A PCB integrated construction offers an efficient design for most non-tactile keypad programs regardless of the key density. In addition to offering more trace routing capability, the PCB can incorporate passive and active components as well as acting as a rigid backer.

For more information on membrane switches please contact Reid Print Technologies on 1300 765 533 or sales@reidprinttechnologies.com.au

Don’t Forget to Follow Us on our socials: Facebook | Instagram | LinkedIn

With the recent technology boom, the demand for lightweight, smart and IoT enabled componentry has increased massively, hence the increased demand for FSR Sensors. These paper-thin sensors have saturated our everyday lives providing the simple innovative solutions that have been needed in a variety of industry. Product designers, engineers and innovators often opt for the flexibly printed force sense resistors due to their size and versatility. Reid Print Technologies manufactures FSR or Force Sensing Resistors to order, with a multitude of resistances, sizes, shapes and configurations on offer.

What are they?

Simple, thin, and flexible. Force Sensing Resistors, also widely known as FSR’s for short, are a resistive sensor that responds to a force that is applied to the active sensing area. In simple terms, a FSR is a sensor that’s resistance changes when pressure is applied to it. FSR’s consist of multiple thin and flexible substrates that have been electronically printed into specific configurations with specialised inks. The force or pressure data that has been collected through the sensors are then measured to give valuable feedback, supplying critical data across a wide variety of industry. Electronically printed FSRs are low cost and versatile to manufacture in a range of sizes, shapes and configurations. This also provides the added advantages of allowing for full customisation where needed.

How are Force Sensing Resistors made?

Force sense resistors by Reid Print Technologies are screen printed onto a flexible substrate with specialised carbon inks. This specialised ink enhances the sensor’s ability to measure the pressure or forces that are applied the active area of the sensors.

What are Force Sensing Resistors used for?

FSRs were created 1977 for musical instruments. Since then, FSR applications have expanded exponentially. You can find FSR technology in a variety of industry including:

- Industrial

- Medical

- Aerospace

- Computing

- Internet of Things

- Robotics

- Wearable Technology

In simpler terms, if there is a need for pressure or force to be measured, force sense resistors can offer an economical, low cost and innovative solution.

What is the difference between Shunt Mode and Thru Mode?

It is important to understand that force sense resistors have two main types, shunt mode resistors and thru mode resistors.

Shunt Mode: Shunt Mode FSR’s are the most frequently used of the FSR family. These resistors are more receptive to a wider range force. The shunt mode FSR is made up of two layers of flexible substrate. Shunt Mode Force Sense Resistors are made by screen printing interdigitated track patterns on one film substrate and the force sensitive elemental ink is screen printed on the another. Each different FSR application requires different configurations and different design materials including the choice of silver, carbon, copper and other ink blends. However, silver conductive ink is the most common material for the shunt mode FSR.

Thru Mode: Thru Mode Force Sense Resistors are manufactured by screen printing a solid conductive pad on each substrate, layered with a force sensitive element faced towards each other. Thru Mode Resistors are more receptive to lighter forces. Although thru mode force sense resistors are less commonly used than the shunt mode, they are the preferable mode when aiming to detect the smaller forces. This is the due to more ink that is required to print the active area of a thru mode FSR. However, with the more ink required, the higher the price point of manufacturing the Thru Mode FSR.

What you need to know about

IoT

The Internet of Things (IoT) is a commonly used term in the world of technology. Everyone is talking about it. But what is IoT and how do we keep up with this evolving technological landscape? According to Investopeidia Internet of Things is “a name for the aggregate collection of network enabled devices, excluding traditional computers”. This industry has been projected to grow to 35.2 billion US dollars in 2025. That is an increase of 15.2 Billion dollars since the 2020 estimate of 20.2 billion dollars. So how do businesses keep up with these technology advancements? What does this mean for your industry? These are the burning questions we all have about IoT.

How does IoT work?

Through connection platforms like Wi-Fi, 4G, 5G, Satellite, Bluetooth, IoT enabled devices or objects are interconnected and able to essentially talk to each other then talk to you. These devices will become your new eyes, ears, and brain. They see, hear, and analyse the data that has been captured and feed back to you. Sounds simple right? That is because it can be.

How does IoT fit in my industry?

Internet of Things is often divided into the four main sectors of consumer, commercial, industrial and infrastructure. To put in perspective the growth of the IoT in industry, it has been predicted by 2025 there will be 75.44 billion IoT devices installed worldwide. This is a wave that everybody should want to catch.

Consumer

You may recognise IoT in your everyday life already. Including Home Security systems, Wearable Technology, Smart Homes and many more. Google Home and Amazon Echo for example are some of the most popular IoT products to date.

Commercial

Commercial IoT is basically everywhere that is outside your home. Supermarkets, boutique stores, that coffee shop on the corner all use IoT devices. Whether it be asset tracking, building security or a wireless EFTPOS machine IoT is has become a fundamental requirement to optimise how a business functions.

Industrial

IoT aims to improve efficiency and productivity in the industrial industry. Some of the industrial sectors include manufacturing, mining, agriculture, smart cities, and many more that do not even exist yet. Industrial IoT is largely refers to the interconnected instruments, sensors, and equipment that all “talk” to each other to improve business processes.

How are printed electronics incorporated into IoT functions?

Reid Print Technologies are well versed in the production of IoT compatible devices. Reid Print Technologies has perfected the design and engineering of a variety of sensors that have full capabilities to be integrated into IoT applications. For example, the following sensors produced by Reid Print Technologies are IoT compatible:

- Temperature Sensors

- Printed Antennas

- Printed Heaters

- Force Sensing Resistors

Opting for an electronically printed solution for IoT can be a cost-effective and productive way to integrate IoT into a variety of functions.

Enquire about IoT Products with Reid Print Technologies today via sales@reidprinttechnologies.com.au or 1300 765 533.

It is no secret that the printed electronic industry has undergone exponential growth. As this industry has expanded, so has the capabilities and applications of the printed electronics. It has been reported by Markets And Markets that the wearable medical device market will reach $46.6 billion dollars by the end of 2025, which is an increase of $18.4 billion from 2020. With so much room to grow, there is no telling what the printed technology industry can achieve. One of the more recent developments of the industry is the use of printed wearable electronics for medical monitoring. These sensors have endless capabilities to assist any medical practitioner that needs to obtain accurate data for medical diagnosis.

An example of this technology in application includes monitoring patient data with wearable technologies. Through incorporating the wearable technology into material items including hospital robes, bed sheets, gloves, socks, and much more. The wearable technology is light-weight and undetectable, removing any patient discomfort. Patient discomfort, stress or anxiety has been medically proven to impact testing results. Printed electronics offers the remedy for this, allowing patients to be comfortable which in turn provides medical practitioners with the most accurate data that technology can provide.

Medical practitioners have been crying out for help, for a solution to their medical monitoring grievances. This is where printed electronics and smart wearable technology offers the benefit of cost effectiveness while incorporating sleek accessible designs.

These possibilities are truly endless. The potential to revolutionise any medical device can and should be done. If you are interested in what our printed electronics can do for you, do not hesitate to contact us, we are always eager to begin new exciting projects.