NFC (Near Field Communication) is a type of Radio-Frequency Identification (RFID) technology. Printed NFC Antennas have various advantages during the process of making electronics systems easily integrated, light-weight, cost-effective, robust and mobile.

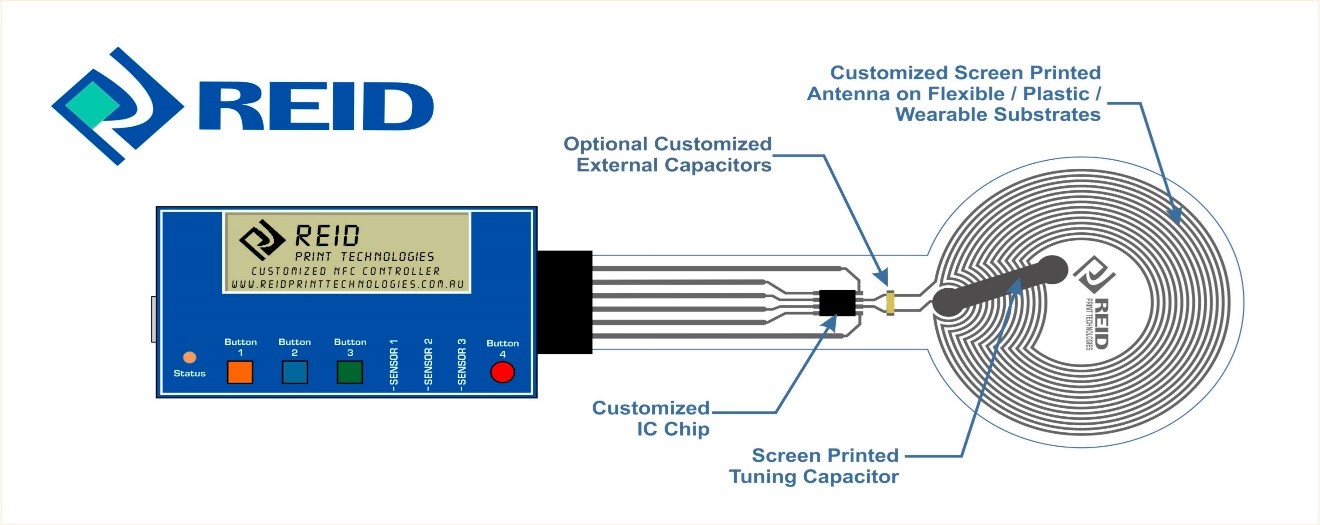

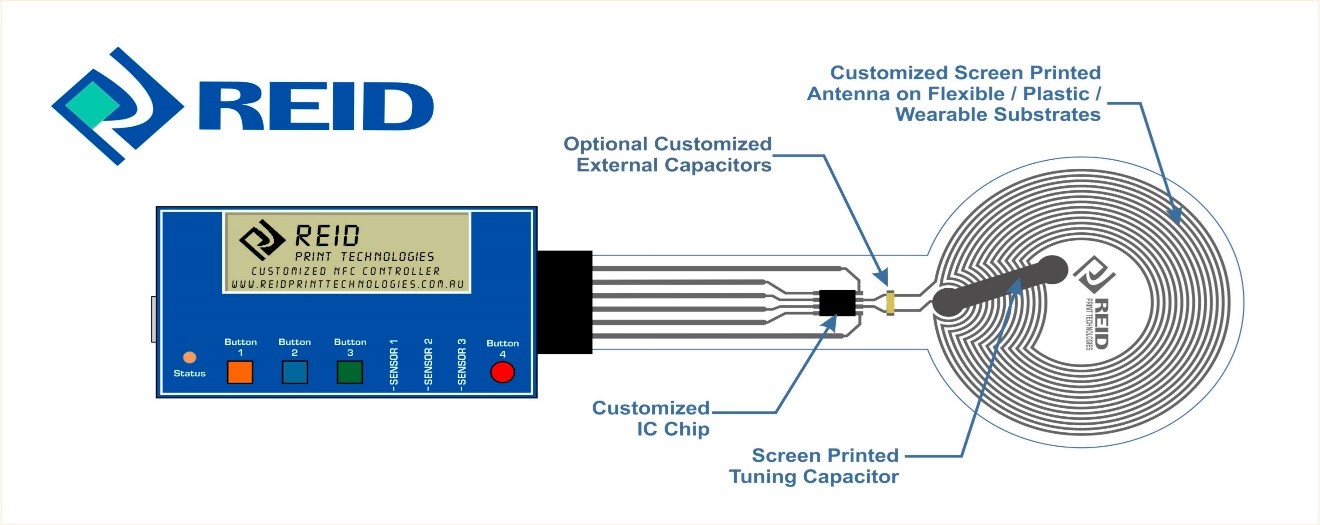

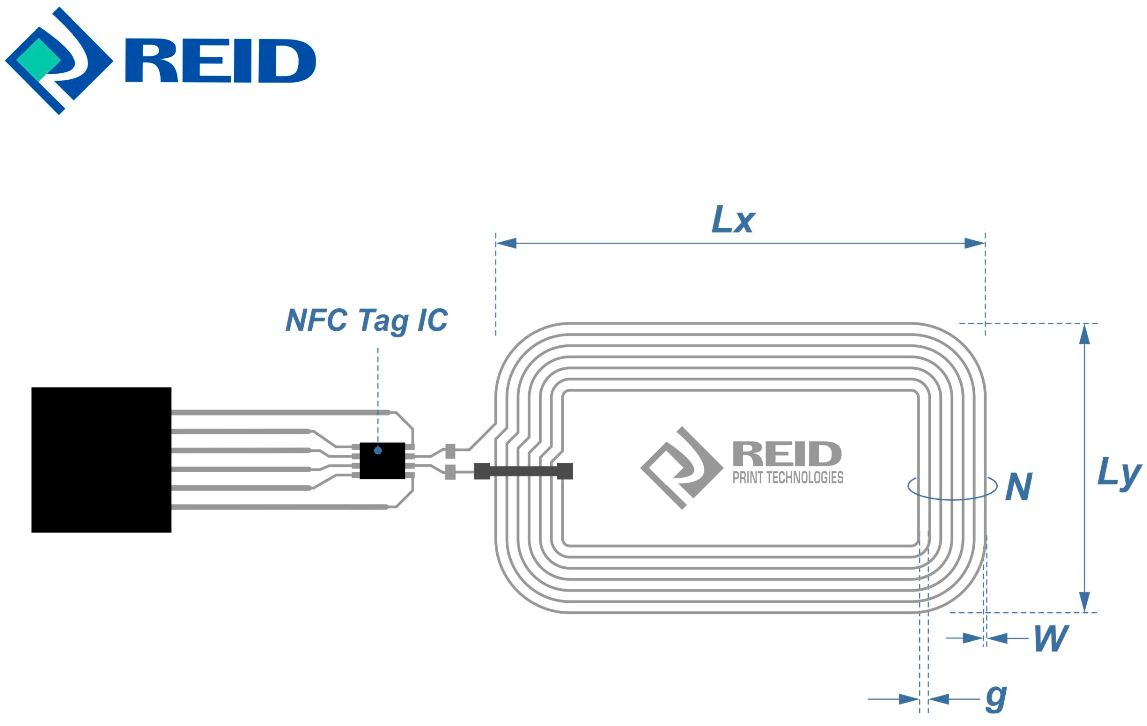

Reid Print Technologies specializes in aiding the system integration process of its clients through the process of design, development, and industrial scale production of various types of flexible printed thin film NFC Antennas for both tags, and reader on the choice of their substrate/surface.

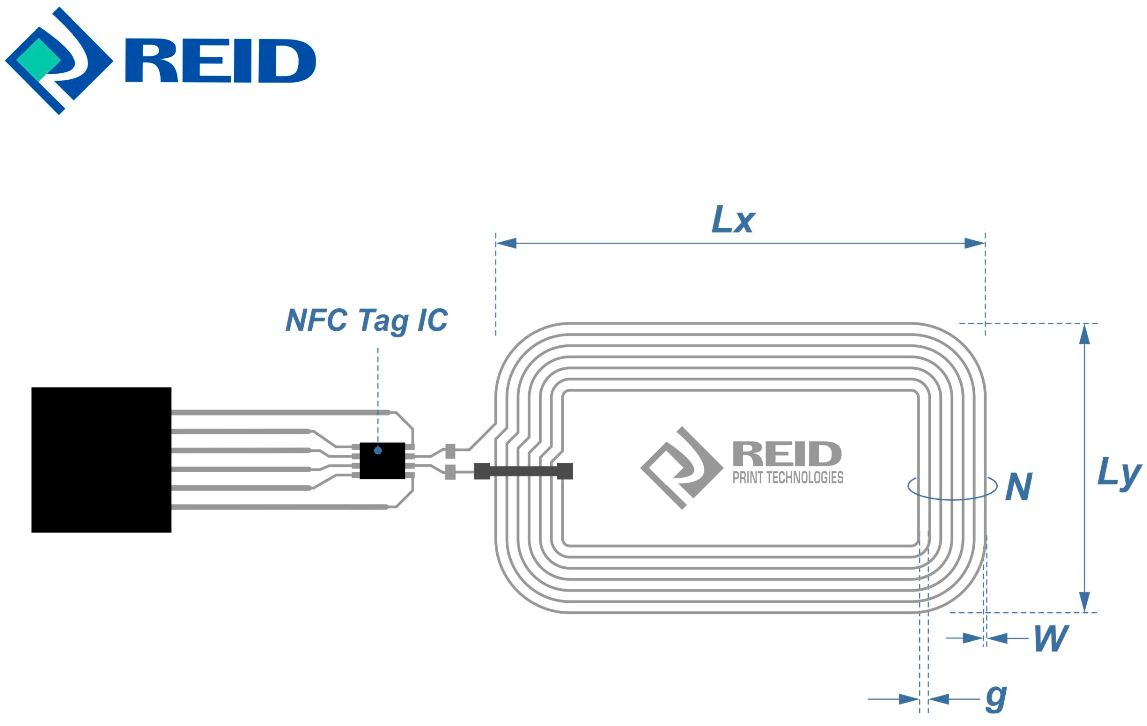

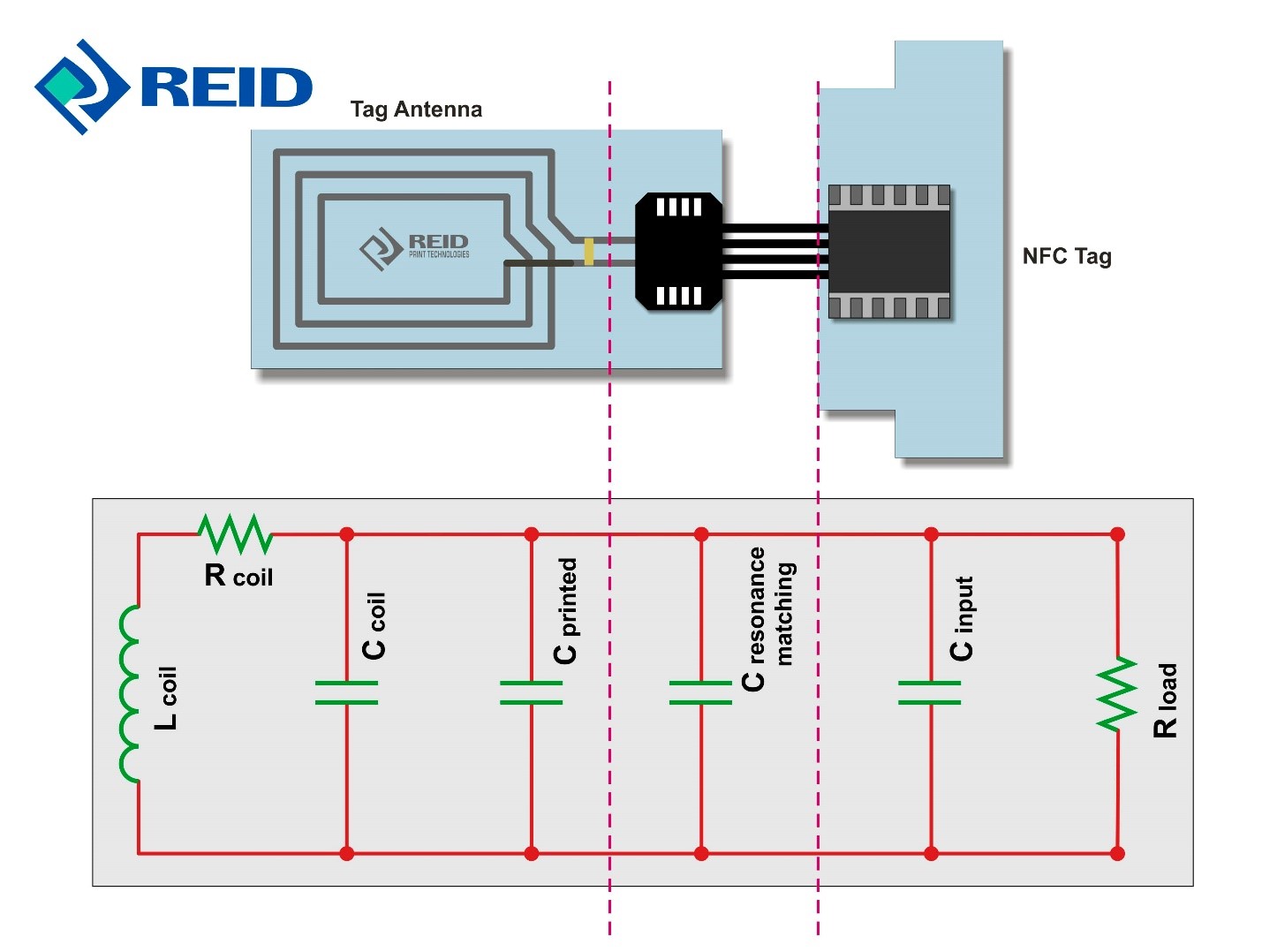

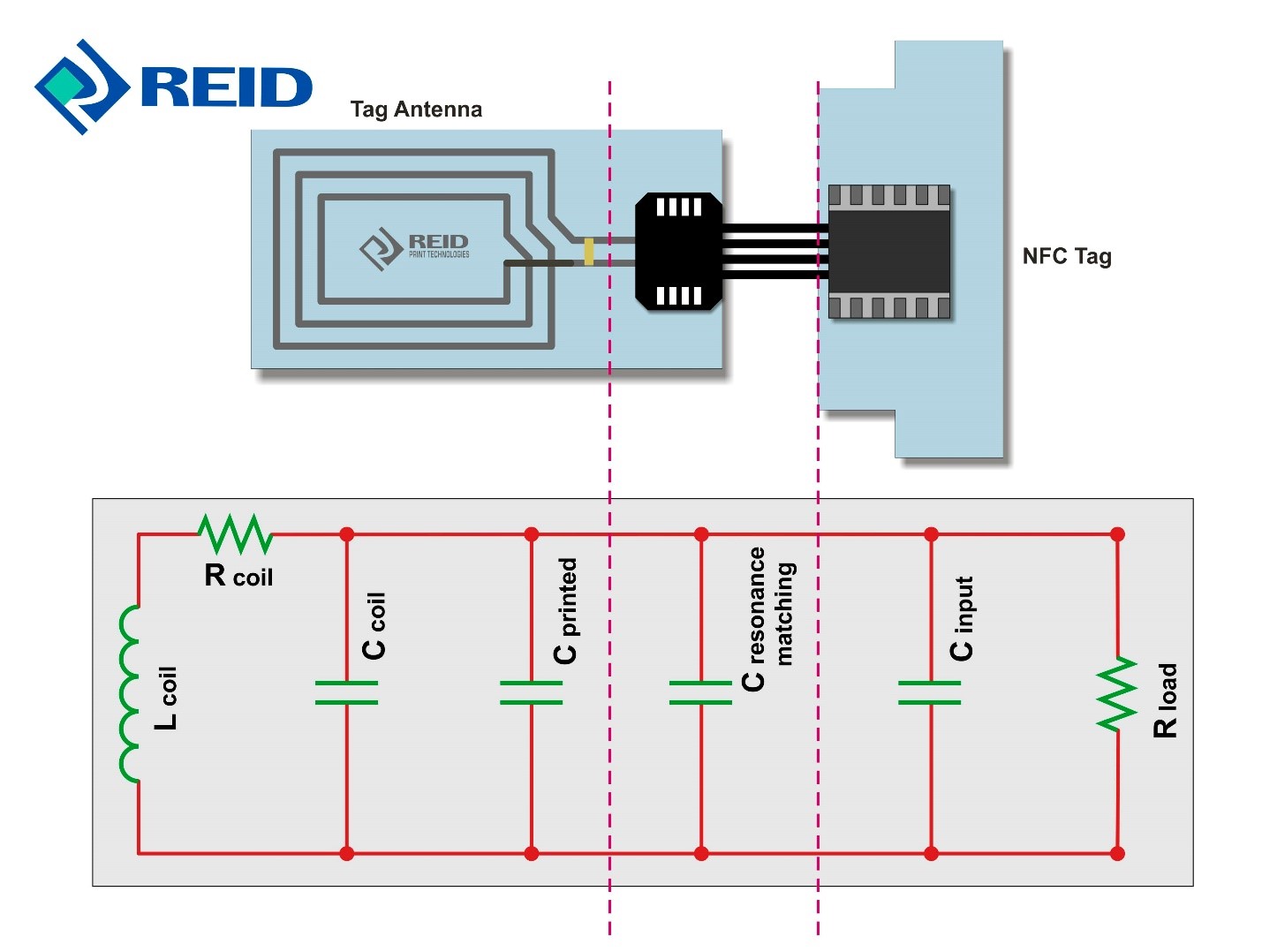

Based on the applications requirement, our proven ability to print a robust capacitor along with Inductor coils enhances the ease of tunability of the entire NFC resonance circuitry without the aid of additional capacitors. We also have the expertise in embedding external capacitors for energy harvesting purposes, along with placing the micro and nano chip at the desired location of the printed NFC circuitry. Thereby, our Printed NFC Antenna solutions can make the systems lighter and agile compared to the bulky antenna made of ferrite, copper, etc.